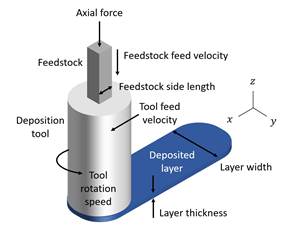

Incorporating AFSD Into Hybrid Manufacturing Processes

By: Tony Schmitz

Additive friction stir deposition (AFSD) is a new, solid-state additive manufacturing process that provides an alternative to beam-based AM processes.

Automatic Sizing Adjustments for High-Volume Lathe Work

By: Mike Lynch

Keeping operators from having to manually make sizing adjustments will free them up to do other things for as long as each finishing tool will last, regardless of how many sizing adjustments it requires.

#cnctechtalk

Digital Comparators are More Than Just Readout Devices

By: George Schuetz

Modern digital comparators often combine the performance of touchscreen phones, LVDTs, digital amplifiers and even small PCs into the size of a standard dial indicator.

#qualitygagingtips

Can ChatGPT Create Usable G-Code Programs?

By: Julia Hider

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Top 10 Modern Machine Shop Articles of 2023

By: Nathaniel Fields

Tips, custom macros and automation topics highlight the top articles published by Modern Machine Shop in 2023.

5 Benefits of Having a Manageable Backlog

By: Udo Jahn

Shops must effectively deal with workloads and not let the backlog grow too large in order to keep customers satisfied.

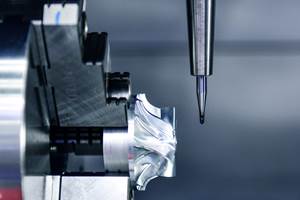

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

By: Evan Doran

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

An Open Letter to Kids About Machines and the World of Making Things

By: Brent Donaldson

This is an open letter to middle- and high-school students about choices they’ll soon face. It is also an introduction to Career and Technical Education (CTE), the world of CNC machining, and a reminder that there are options outside of the traditional four-year college path.

#thesetup

Medical Shop Performs Lights-Out Production in Five-Axes

By: Eli Plaskett

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

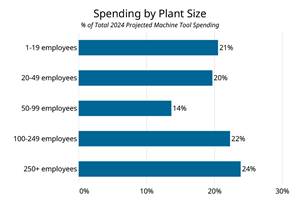

Large Plants Plan High Rates of Capital Spending in 2024

By: Jan Schafer

Gardner Business Media’s Capital Spending survey projects a modest decline of 7.4% in machine tool spending next year. While job shops are taking a wait-and-see posture, large plants plan robust spending with machining centers leading the way.

Controlling Extreme Cutting Conditions in Large-Part Machining

By: Brent Donaldson

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

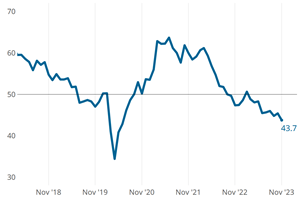

Metalworking Activity Remained on a Path of Contraction

By: Jan Schafer

Steady contraction of production, new orders and backlog drove accelerated contraction in November.

#economics

Hermle Event Encourages, Educates on Five-Axis Machining

By: Julia Hider

Hermle’s first Five-Axis Summit was designed to show beginners the benefits of five-axis machining and demonstrated how more advanced users can take their capabilities to the next level with automation.

Random Thoughts on Manufacturing, Innovation, What We Appreciate, and More

By: Peter Zelinski

Here are several mini-columns merged into one. Take these thoughts all at once or in small doses.

#zaxis

High-Feed Machining Dominates Cutting Tool Event

By: Eli Plaskett

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

The Keys to Combining High- and Low-Volume Production

By: Julia Hider

Process expertise and precise production planning enable the Kinetic Company to produce both high- and low-volume jobs requiring machining, grinding, heat treatment and other processes.

Combining Functions With User-Defined G & M Codes

By: Mike Lynch

CNC programmers gain flexibility when using custom macros to define G and M codes themselves.

#cnctechtalk