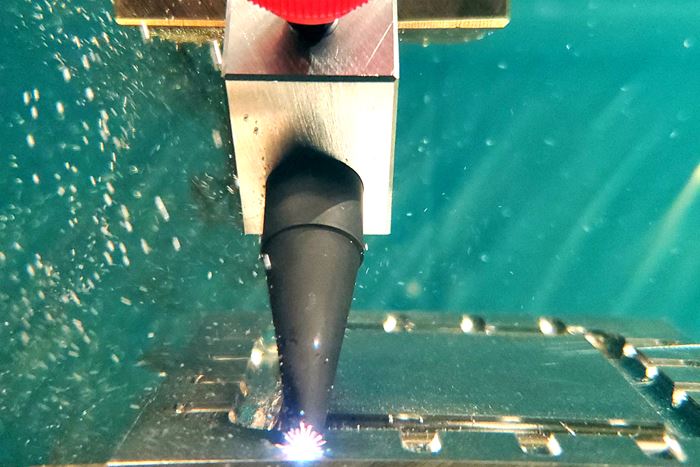

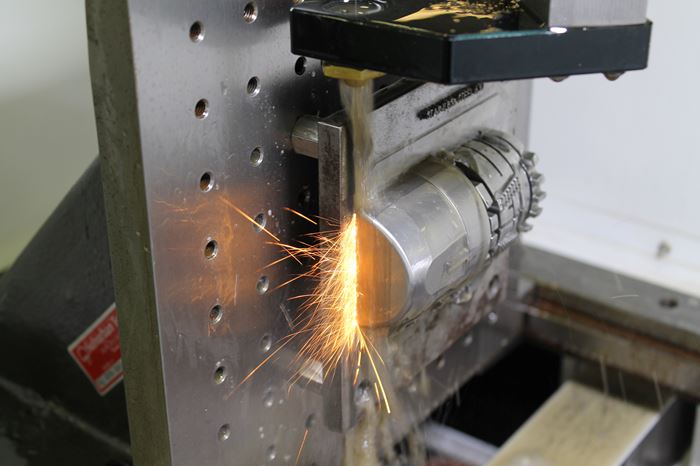

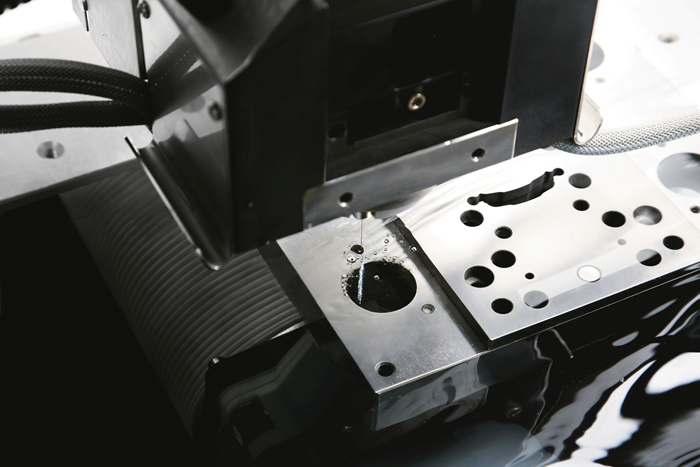

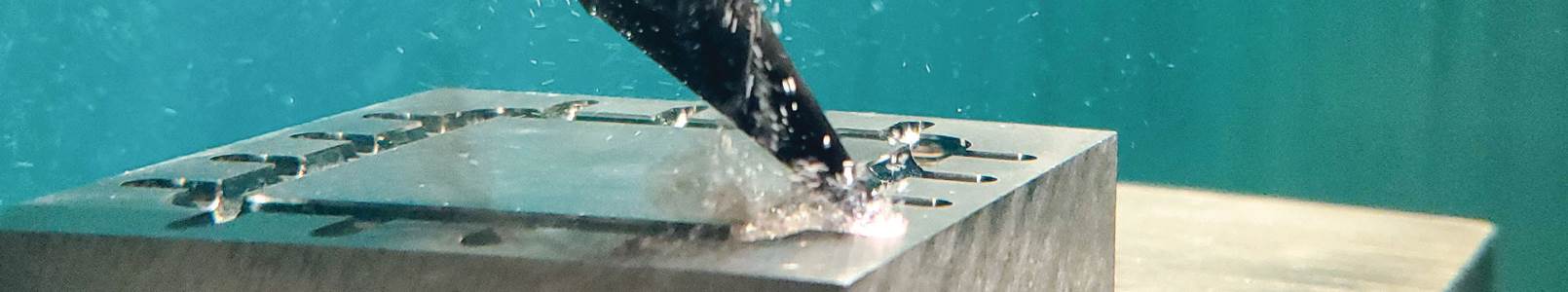

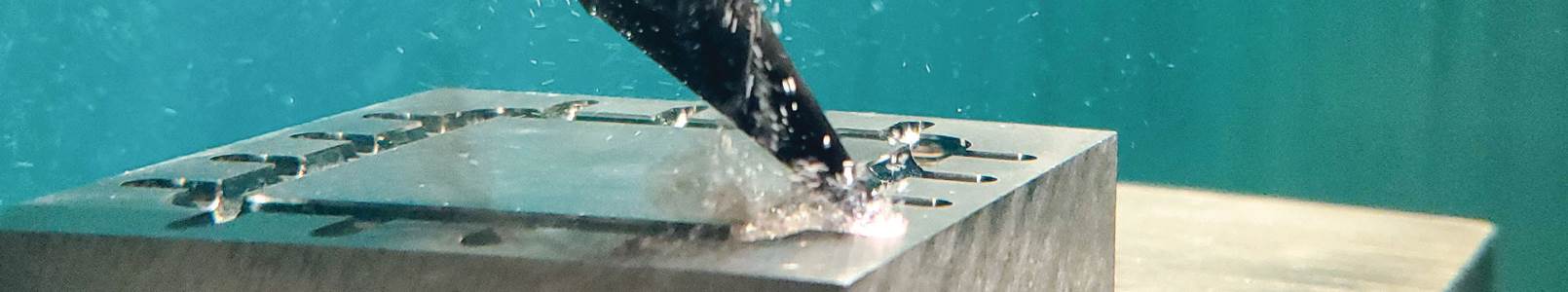

EDM, or electrical discharge machining, is capable of machining complex shapes in hard materials. The process includes an electrode and a workpiece, both submerged in dielectric fluid. Electrical current flows between the workpiece and electrode, repeatedly creating tiny plasma zones that instantaneously melt and remove the material. The electrode in EDM takes different forms. Wire EDM machines use a thin wire to cut. Ram EDM machines, or “die sinkers,” use electrodes that are custom machined into 3D shapes. The EDM process produces a cavity in the part that is the opposite or female version of the “male” electrode form. Similar to the ram EDM machine is the small-hole EDM machine, or “hole popper.” On this machine, the electrode is a cylinder used to machine a hole.

Cool Tricks: How to Photograph Sinker EDM

Sometimes it takes a little extra effort and ingenuity to solve a problem. In the case of the February 2020 cover of Modern Machine Shop, it took a lot of each — and a cheap plastic spaghetti container.

EDM: Essential Reading

Inside the Sinker EDM Process, One Spark at a Time

Successful sinker EDM operations rely on understanding the relationship between each individual spark, the electrode and the workpiece.

CAM Simulation Gets Toolmaker up to Speed with B-Axis EDM

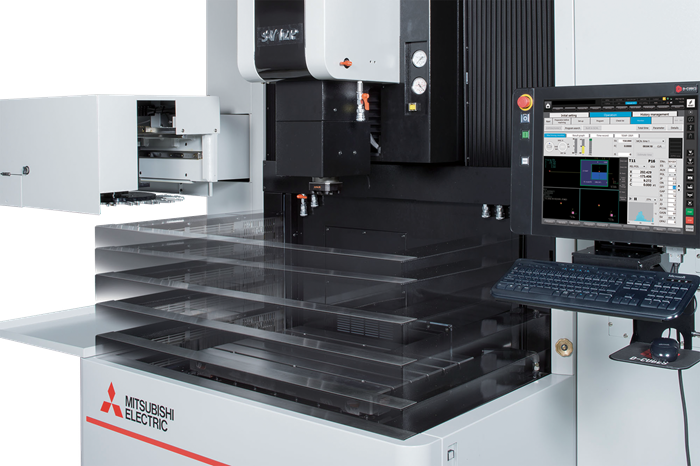

Software simulation helped this machine shop learn how to program its new advanced, high-tolerance wire EDM. The software also helped the shop turn job quotes around quickly.

Buying a Wire EDM, Part 4: Dielectric Fluid & Maintenance

Removing the microscopic particles made during the wire EDM cutting process becomes a key factor in maximizing cutting speed as well as attaining part accuracy and surface finish. Dielectric fluid is the mechanism for flushing these “chips” away.

Buying a Wire EDM, Part 3: Speed, Accuracy and Finish

What kind of surface finish can the purchaser of a wire EDM expect with today’s technology?

Buying a Wire EDM, Part 2: Wire Considerations

Each type of EDM wire has its strengths and weaknesses. This post reviews wire types, the importance of tensile strength and wire rethreading.

FAQ: EDM

What is EDM?

Electrical discharge machining, or EDM, is a non-contact process that can machine parts regardless of their hardness. It involves placing an electrode or wire and an electrically conductive workpiece into a circulating dielectric fluid. The fluid acts as an insulator until a specific spark gap and voltage ionizes it and enables a spark to travel to the workpiece.

Using a CNC, the operator moves the electrode or wire as needed and rapidly turns the current on and off. This accommodates the flushing of molten material (often called “swarf”) from the workpiece.

Source: Machining 101: What is Electrical Discharge Machining?

What are the two types of EDM machines?

The two main types of EDM machines are sinker EDM machines and wire EDM machines.

Source: Machining 101: What is Electrical Discharge Machining?

What is sinker EDM?

Sinker EDM uses an electrode as its “cutting” tool, with the shape of the electrode serving as a mirrored, slightly smaller image of the finished form it will produce in the workpiece. The electrode makes one spark at a time — but the frequency of the current means the tool could produce anywhere between 500 and 30,000 sparks per second.

Electrodes for sinker EDM are typically either copper or graphite.

Source: Machining 101: What is Electrical Discharge Machining?

What is wire EDM?

Wire EDM feeds a strand of wire from a supply spool to the workpiece via a wire drive system. The wire is energized by electrical contacts and passes through the workpiece at a specific velocity determined by the operation at hand. A stream or bath of deionized water surrounds the wire, and sparks are continuously emitted along the length of the wire. Rollers pinch the wire and provide tension, while guides above and below the workpiece position the wire on its path — helping it to achieve complex shapes on the workpiece.

The wires used in this process commonly have diameters of 0.010 to 0.012 inch, with finer wires at 0.001 to 0.004 inch. The material of the wires also holds great influence over the operation’s success, as hard wires that have insufficient tensile strength for an operation are liable to break under sudden shock. Softer wires prove more desirable for high-taper cutting operations.

Source: Machining 101: What is Electrical Discharge Machining?

What is swarf?

During the EDM process, the operator moves the electrode or wire as needed and rapidly turns the current on and off. This accommodates the flushing of molten material (often called “swarf” or “chips”) that is removed from the workpiece.

Source: Machining 101: What is Electrical Discharge Machining?

EDM Suppliers

Voice Activated Machine Interface Comes to Machine Tools

Voice-enabled virtual assistants are coming to machine tools. Now available on Makino wire EDMs, the ATHENA interface promises to help manufacturers better utilize their equipment, aid less skilled workers and operate more machines with fewer people.

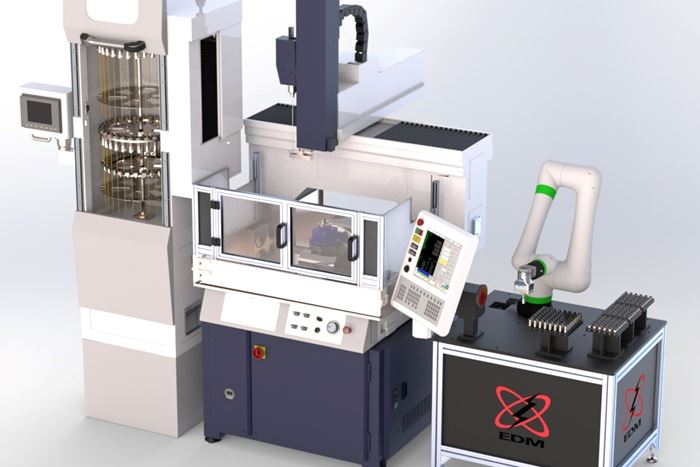

Robot Frees EDM Drill From Machine Enclosure

CNC integration with a six-axis arm provides precise enough positioning to shape air- and gas-flow holes in aerospace and power generation parts.

GF Machining Solutions Debuts Automation-Forward EDM

With more than 600 pre-programmed cutting processes, the Cut P 550 Pro covers a wide range of parts in materials such as steel, carbide, copper, aluminum, titanium, polycrystalline diamond (PCD) and graphite.

New Five-Axis Milling Machine, Horizontal Wire EDM for Medical

GF Machining Solutions’ Mikron Mill E 500 U five-axis milling machine and Cut AM 500 horizontal wire EDM are designed to work seamlessly alongside the company’s additive manufacturing systems for complete medical part processing and optimized workflow.

EDM Network's Wire EDM Series Provides Reusable Wire

The EDMMax 434W is a four-axis wire EDM that uses a 0.007" diameter molybdenum wire, which draws the water-based dielectric through the cut, cooling it and pulling the small chips out of the kerf at a very fast rate.

Rapid Metal Parts Removal With EDM Network Inc.'s New EDM

According to EDM Network Inc., the Fast Wire EDM is capable of cutting speeds that are two to three times faster than traditional wire EDMs.

Automation Adds Capacity to Capability for Low-Volume Work

Investment in machining technology has facilitated growth and diversification at Reich Tool & Design. Now, flexible automation allows the shop to get more out of its machines despite a shortage of skilled workers.

#topshops