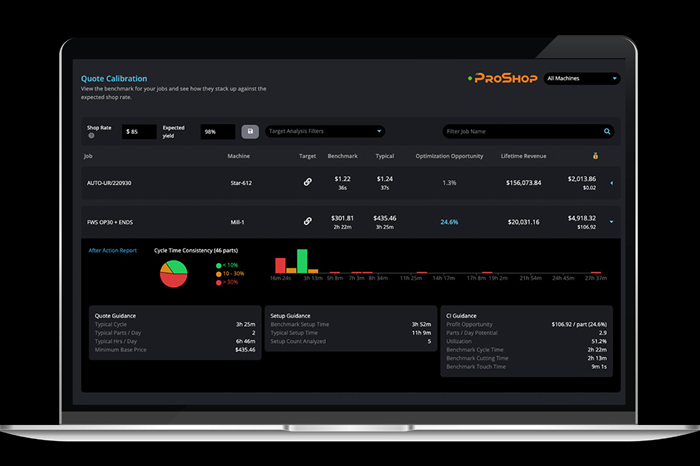

ERP stands for “Enterprise Resource Planning.” Some of the functions associated with ERP and related management software include: Costing or estimating the time and cost of production, scheduling a job for production, and in-process job tracking, or logging each step in a part’s progress through the shop, so a part’s current status can be immediately known. ERP systems also provide a historical view of resources required on prior jobs which can be very helpful in planning new work.

5 Reasons Why Machine Shop Ownership Is Changing

Mergers, acquisitions and other ownership changes are an effect of Boomer-age shop owners retiring, but only in part. Also important: The way we think about machining has changed.

Shop Management Software: Essential Reading

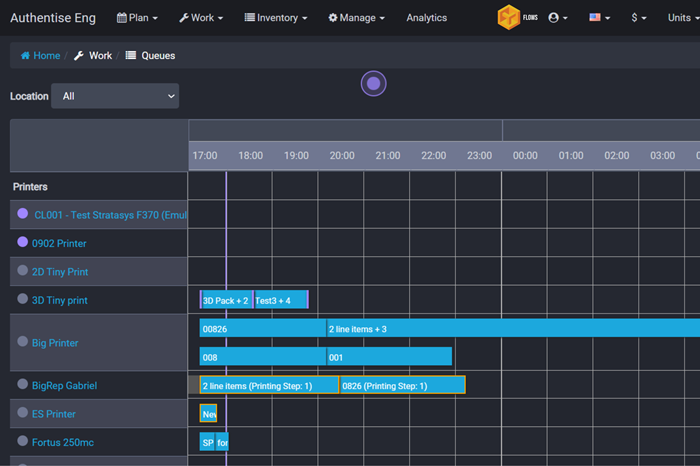

How to Grow the Business with Real-Time Job Status Data

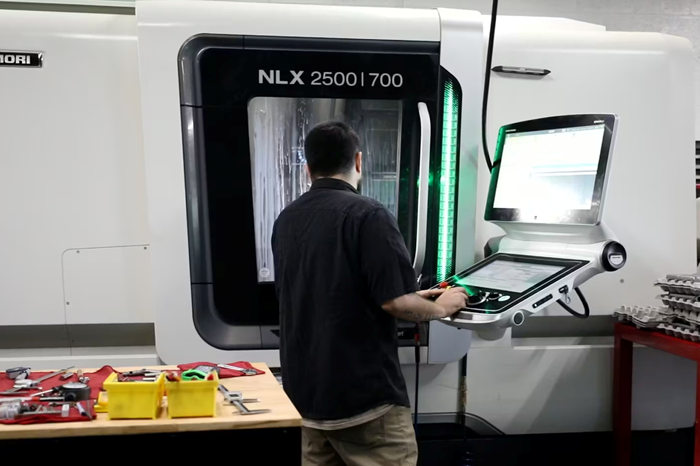

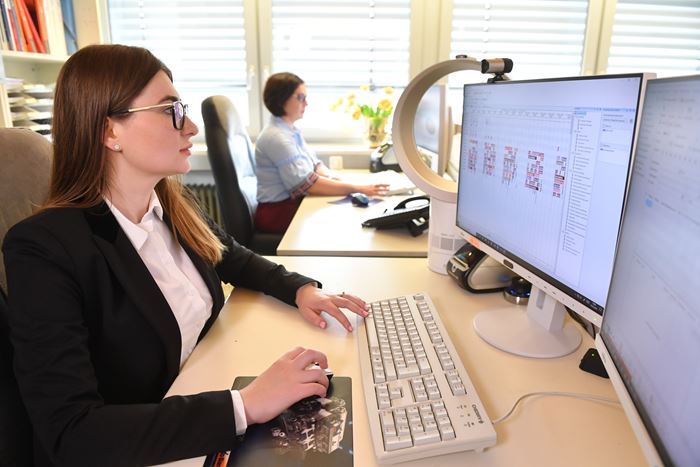

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

How to Scale a Job Shop for Growth with Fewer People

Front office disorganization and poor shop floor communications don’t just reduce a job shop’s efficiency; they are a barrier to growth. Having the right kind of ERP system can be the key to improving profitability and scaling for future growth

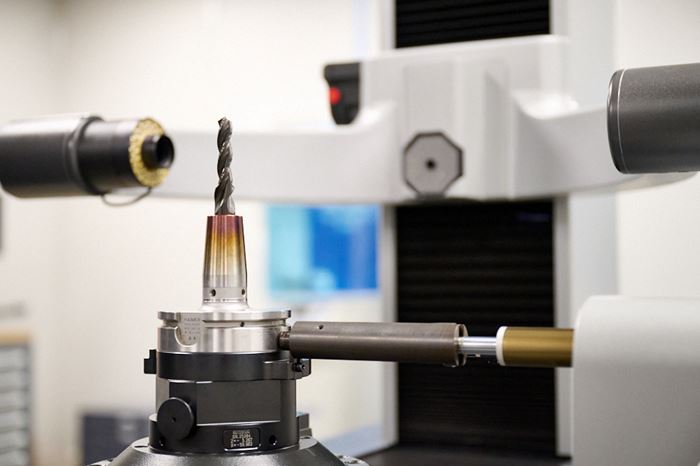

How To Find The Right Solid Carbide Tool For Your Production

Watch this demo for an inside look at Sandvik Coromant’s advanced solid carbide tools like CoroDrill 860-GM – designed for fast and problem-free drilling, maximizing productivity through high metal cutting efficiency. (Sponsored)

3 Reasons Machine Shops are Paying Attention to ERP

Awareness of people and the value of their efforts accounts for part of the reason why we are seeing enterprise resource planning being taken more seriously.

Inside the Sinker EDM Process, One Spark at a Time

Successful sinker EDM operations rely on understanding the relationship between each individual spark, the electrode and the workpiece.

FAQ: Shop Management Software

What does ERP stand for?

ERP stands for enterprise resource planning.

Source: How to Choose an ERP System for Your Data-Driven Machine Shop

What is ERP?

ERP stands for “Enterprise Resource Planning.” Some of the functions associated with ERP and related management software include: Costing or estimating the time and cost of production, scheduling a job for production, and in-process job tracking, or logging each step in a part’s progress through the shop, so a part’s current status can be immediately known.

What should you consider before choosing an ERP system?

- Consider your objectives and requirements.

- Measure return on investment (ROI).

- Speak to fellow ERP users.

- Scrutinize the demo.

- Calculate the real cost (up-front costs, maintenance, recurring costs, etc.)

Source: How to Choose an ERP System for Your Data-Driven Machine Shop

What should you look for in your ERP system?

- Integration

- Maintenance and Scheduling

- Parts Tracking and Job Tracking

- Document Management

- Material Control and Inventory Management

- Data Collection

- Business Intelligence

Shop Management Software Suppliers

Narrow by Shop Management Software Category

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

FactoryWiz Monitoring System Reduces Operator Errors

Eastec 2023: FactoryWiz provides real-time monitoring and data analysis to give manufacturers insight into the production process and help them make informed decisions.

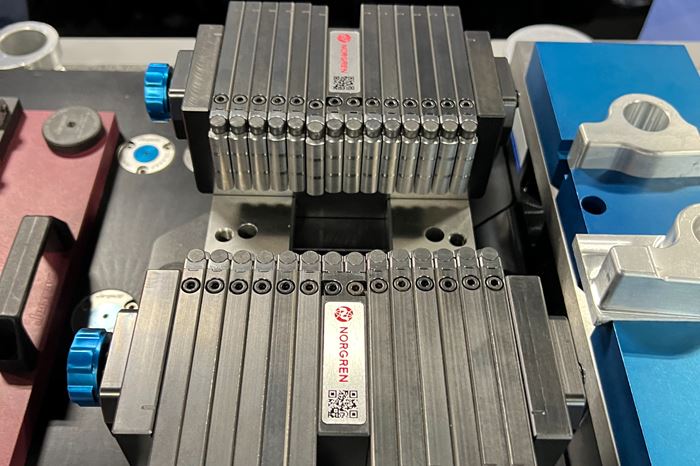

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

#workforcedevelopment #zaxis

Shop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

#successionplanning #workforcedevelopment

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

#workforcedevelopment

NUM Launches CNC Platform With Enhanced Machine Control

FlexiumPro enables control of up to 32 axes and/or spindles, up to 32 machining channels and sub-nanometer interpolation capabilities.