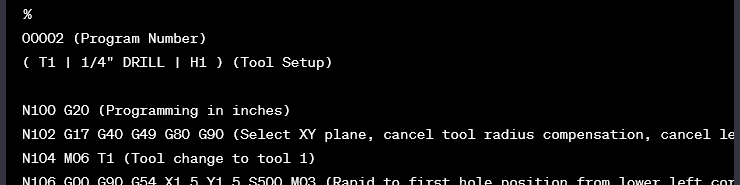

Combining Functions With User-Defined G & M Codes

CNC programmers gain flexibility when using custom macros to define G and M codes themselves.

#cnctechtalk

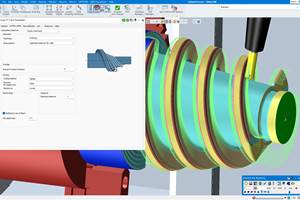

Concepts NREC Software Facilitates Efficient Machining

The updated Agile Engineering Design System enables engineers to explore some of the cycles that have the potential to reduce carbon emissions in all applications.

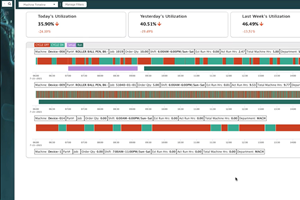

Beckhoff Automation Software Simplifies Programming

The TwinCAT 3 CNC cycle package supports a variety of different drilling strategies, ranging from simple centering and deep-hole drilling to tapping, helical and thread milling.

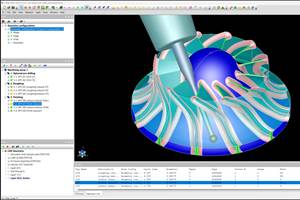

Okuma America Control Features Digital Twin Technology

The OSP-P500 control features dual-core processors that provide redundant operations, ensuring uninterrupted machining operations.

.jpg;maxWidth=970;quality=90)