At a recent event announcing its latest product lines, Ingersoll Cutting Tools made one thing clear: it sees high-feed machining as the future of metal manufacturing.

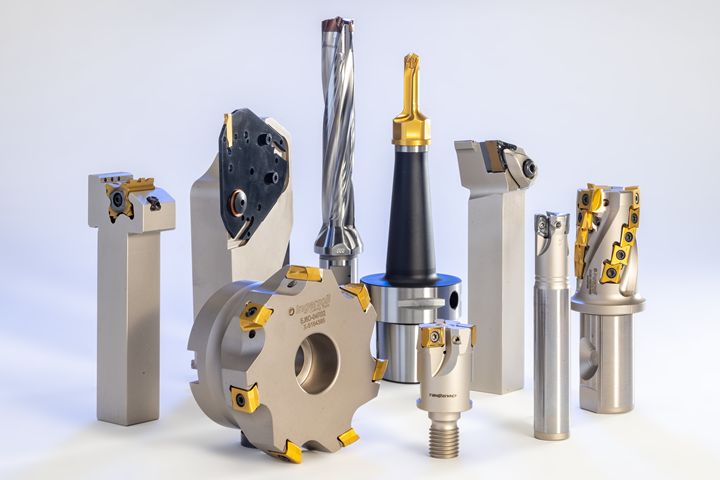

The New Product Rollout showcased dozens of new and updated cutting tools, with high-feed machining as one of the major highlights. According to Jacob Harpaz, the benefits of this advanced machining strategy will only increase its popularity with shops. Photo Credit: Ingersoll

During the New Product Rollout in Rockford, Illinois, Jacob Harpaz — chairman and CEO of IMC Group, the parent company of Ingersoll — discussed the importance of continuously developing new technology. “We must innovate with the purpose of increasing customer profitability,” he says. To illustrate this, he discussed a wide range of new and current cutting tools that reduce machining time, focusing especially on high-feed machining.

Featured Content

High-Feed Machining

According to Harpaz, 75% of the cost of making a part is fixed, with the largest variable cost being the time to machine the part. That makes reducing production time the most effective way to reduce the cost of a part, which guides Ingersoll’s cutting tool designs.

And Harpaz firmly believes that high-feed machining is the way to reduce production costs.

High-feed machining is a machining strategy that uses chip-thinning cutting tool geometry to enable exceptionally high feed rates, typically with a high lead angle and shallow depth of cut. Machinists using this strategy have been able to both increase productivity thanks to the higher metal-removal rate and increase tool life thanks to the constant chip load of high-feed toolpaths.

Ingersoll has fully embraced this machining strategy, announcing the release and updates of dozens of high-feed cutting tools in many sizes over the course of the evening. Dubbing these new high-feed options the WinSFeed line, it combines the tool life of the SFeed material grades with high-feed geometries.

The DiFeedWinV, for example, is a 90-degree indexable end mill designed for the die/mold industry. Based on the existing DiPosFeed line, it is designed for milling in deep cavities, but Harpaz says the V-shape of the insert pocket provides even greater rigidity and enables even higher feed rates than the DiPosFeed line.

This was only one of dozens of new high-feed tools available. Others include:

- GoldSFeed – A thick, four-edged insert for high-feed machining of titanium, stainless and exotic materials.

- CeraSFeed – A high-feed ceramic insert designed for nickel-based alloys and superalloys.

- WinTurn – A double-sided triangular insert capable of both multidirectional and high-feed turning.

- WinCut – A highly rigid, single-ended parting system that provides higher feed rates by directing cutting forces into a triangular blade and block.

- GoldTwin – A large-hole indexable drill that uses both a self-centering carbide tip and a pair of square inserts for four total cutting edges and two chip channels.

The event saw dozens of new cutting tool options, including numerous high-feed machining inserts, modular milling options, drills, and tools for turning, parting and grooving. Photo Credit: Ingersoll

With nearly every tool discussed, Harpaz emphasized the shallow depth of cut and constant feed rate, hammering home the company’s confidence in high-feed milling. He even advised using the higher tool life of the lines on display to push the cutting tools even harder. “It’s not about saving tool costs, but reducing production costs,” he says. Doing so reduces the tool life to what might be expected without the treatment, but increases productivity and therefore profitability, in his opinion.

With all these cutting tools on display, it was difficult for any one cutter to stand out, but Harpaz’s excitement for barrel-style cutters was especially high.

High-Feed Indexable Barrel Cutters

Harpaz discussed both solid-carbide barrel-style end mills and indexable milling tools that emulate the barrel-shaped profile, praising both for enabling shops to dramatically increase production speed over ballnose end mills. “We are in love with the barrel because the barrel is so fast,” he says.

Barrel cutters — also known as circle-segment cutters — are end mills with conical shapes designed to replace ballnose end mills in five-axis machining applications, especially in the aerospace and die/mold industries. They are known for large stepovers that dramatically improve cycle time, which is why Harpaz believes they will only grow in popularity.

“Barrel finishing lets you finish with four times the step height,” Harpaz says, “saving 75% of passes.” He goes further: “I predict that the ballnose will disappear.”

Ingersoll seems to take this claim seriously, as it introduced multiple indexable barrel-shaped cutters to serve this niche:

- DiposProB – An indexable milling cutter with four slots for oblong inserts that imitate the profile of barrel cutters. The large radius enables highly productive cuts.

- FineMold+ – A finishing tool for ballnose inserts now includes barrel-style cutting inserts that take advantage of the large stepovers of barrel cutters.

- ChipSurfer Barrel Cutters – Solid carbide barrel heads for the modular ChipSurfer line. This line enables operators to switch out cutting tool heads on a single shank and now includes a number of barrel cutter options.

Like the high-feed milling options, these barrel cutters lean into newer approaches to machining that promise to dramatically improve productivity. Clearly, Ingersoll hopes that its tooling combined with these machining strategies will enable shops to stay competitive in the modern metal manufacturing marketplace.

RELATED CONTENT

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Sandvik Coromant on Acquisitions: Solutions Entail More Than the Tool

A Q&A with global president Helen Blomqvist explores the cutting tool maker’s acquisition of CAM software companies and how this connects to, among other things, electric vehicles.

-

Cutting Tool Maker Succeeding With 3D Printed Carbide for Oil/Gas and Other Applications

Powders, parts and products are different ways the company is advancing with AM. Carbide and tools are separate areas of success.

.1692800306885.png)

.1687801407690.png)