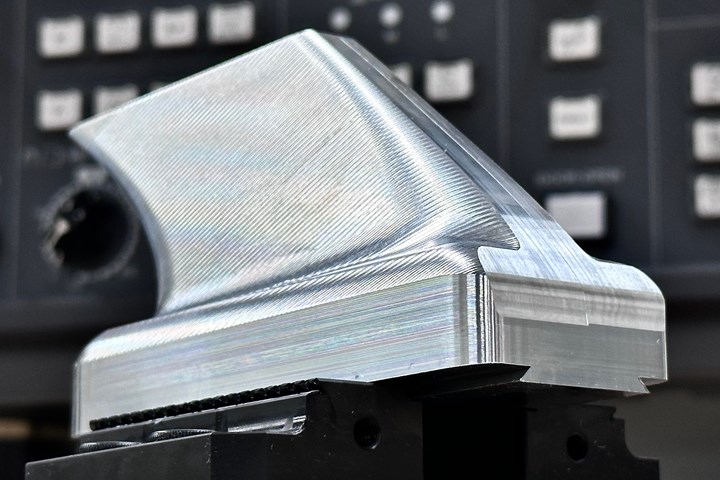

Chiron Compact Machining Center Provides Efficient Production

Westec 2023: The Micro5 five-axis machining center is designed for applications where delicate parts require autonomous machining with optimal surface quality.

Chiron America Inc.’s compact Micro5 five-axis machining center is designed for applications where delicate parts require autonomous machining with optimal surface quality, such as medical and precision engineering, as well as jewelry and watchmaking sector and more.

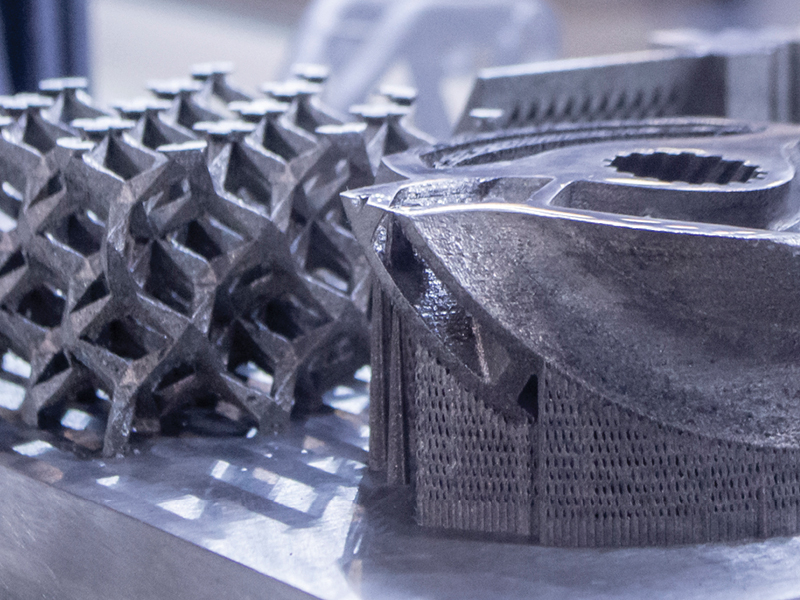

The accompanying six-axis Feed5 handling robot feeds workpieces and tools into the micro-machining center automatically, enabling more productivity, particularly when machining delicate workpieces in a large series. One handling system can equip up to two Micro5 units with blanks measuring up to 50 × 50 × 50 mm, enabling up to 60 tools in total to be changed in less than five seconds. According to Chiron America Inc., the autonomous production solution requires very little energy and space.

RELATED CONTENT

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

Choosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

-

Buying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

.jpg;maxWidth=970;quality=90)

.1692800306885.png)

.1687801407690.png)