The Art and Science of Hand-Scraping Ways on CNC Machine Tools

Hand-scraping the mating surfaces of a CNC machine tool’s motion system offers myriad advantages.

In an age of computer numerical controls and automated processes, hand scraping mated surfaces on a machine tool might seem a bit antiquated. Many OEMs have abandoned it, in fact, pointing to the extra time and effort the operation requires. Some still stand by its value, however, claiming that the craftsmanship involved—and the benefits it provides—cannot be duplicated mechanically. So what is hand scraping, and is it a feature that buyers should seek out when considering the attributes of a new machine tool?

Hand scraping is a manual process of truing and providing texture to mated surfaces in a machine tool. It is most often performed using a flat scraper, which is a hand tool with a flat-edged tip similar to a wood-carving tool. The tip of the scraper is generally an inch wide or smaller, matching the width of the metal shaft—which can be of various lengths—for rigidity. The person performing the operation holds the tip of the scraper firmly against the surface to be worked with one hand while grasping the tool handle with the other, thrusting the tool against the surface with powerful strokes using the body’s weight in order to create a pattern. Other tools used for hand scraping include a three-corner scraper, which is often used to deburr holes, and a curved scraper that can treat the surface of bush bearings.

Featured Content

Understanding Hand Scraping

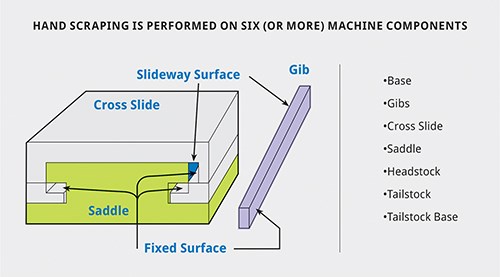

According to Okuma America Corporation—a longtime advocate for the process—the main reasons for hand scraping mated surfaces have to do with oil retention, stability and accuracy. Once the two castings have been joined, the upper piece is coated with engineer’s blue—the pigment Prussian blue in an oil base—and rested atop the way on which it will ride during operation. The resulting imprint reveals areas of contact, allowing the hand scraper to true the surfaces so that they are properly mated but also to create pockets or slight depressions in which oil can pool while its surface tension is retained. This enables a smooth, gliding movement and helps avoid the “slips and starts” caused by contact between perfectly flat surfaces from which lubricants tend to be squeezed. This causes the metal surfaces in contact with one another to grab and seize. The ideal, for most machine tool slideways, is to create approximately eight points of contact between the mated surfaces per square inch, providing flatness and stability and preventing rocking. Typically about six components within an average machine tool will have surfaces to which hand scraping can be applied.

The Difference Between Scraping and Machining

So, isn’t it possible for this manual surface-finishing procedure to be performed by a machine? Some OEMs do just that, machining oil grooves into flat surfaces, while others have transitioned completely to precision linear rails that can be mounted with screws and replaced when they become worn. There are also power tools that can be used to produce an oil-trapping surface texture. The obvious questions involve how machined channels affect surface integrity and whether accuracy is compromised toward the end of a linear rail’s service life. Lapping is sometimes used, but it tends to address the entire surface without creating the high contact points so useful in achieving stability, and it is not ideally suited for creating long, flat surfaces.

Probably the most convincing reason for seeking out hand-scraped mated surfaces in new machine tools involves the fact that the castings used in these applications are, by their very nature, somewhat irregular in their geometry. In addition, the grinding and machining methods used to simulate hand scraping can introduce contracting, flexing and expansion of material—and, later, distortion. So the logical conclusion here may be that the art of hand scraping still has a place in the science of building accurate, reliable, long-lasting machine tools.

RELATED CONTENT

-

Four New High-Performance Milling Techniques for 3D Machining

With many 3D milling applications demanding both shorter cycle times and smoother surface finishes, it’s time to review how you go about programming and machining parts. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes.

-

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

-

Which Five-Axis Machining Center is Right for You?

With so many choices in five-axis machining technology, how do you know which is best for your shop? First, consider the parts. Then, look at existing processes and potential five-axis benefits.

.1692800306885.png)

.1687801407690.png)