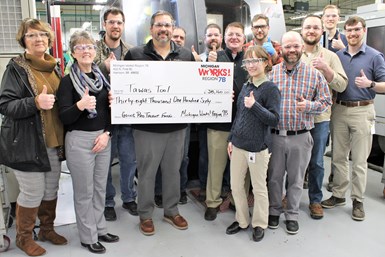

Star Cutter Receives Grant for Employee Training

The Going Pro funds assist employers in training, developing and retaining current and recently hired employees.

#workforcedevelopment

Star Cutter announces that its Tawas Tool, Ossineke Industries and H.B. Carbide facilities have received 2023 Going Pro Talent Funds from the Department of Labor and Economic Opportunity-Workforce Development (LEO-WD) through the Michigan Works! agency. The Going Pro funding source assists employers in training, developing and retaining current and newly hired employees. Past statistics from employees trained through the program indicate a retention rate of over 80%.

“The Going Pro grant funding is an excellent opportunity for Star Cutter to invest in training for our most important assets, our employees,” says Lindsey Bielby, human resources manager. “The funds provided cover a wide range of our training needs as we continue to develop our employees’ skill sets and career paths.”

Tawas Tool Company, a designer and manufacturer of gear tools, is using the funds to provide education through 18 different online courses at the Michigan Manufacturing Technology Center (MMTC), where it will become certified in everything from ISO 9001 Auditing to Blue Print Reading to Introduction to Collaborative Robotics. Additionally, selected employees will attend classes in electrical studies and industrial safety at Alpena Community College.

At Ossineke Industries, Star Cutter’s deep hole drills manufacturing location, funds will be used to provide Solidworks CAD Program training to two employees, as well as sending four employees to classes at the MMTC in ISO 9001: 2015 Internal Auditor, 8-D Problem Solving and Core Tools training. Additionally, Ossineke plans to hire two new team members, and these funds will enable them to receive six weeks of cross-training on different plant responsibilities

At the H.B. Carbide facility, where the company manufactures tungsten carbide blanks and preforms, the funding is being used to provide training to two new team leaders in the areas of Lean Office Practitioner, Lean Manufacturing Practitioner and Lean Single Method Exchange of Die, SMED.

In addition to the training being provided through the Going Pro funding, Star Cutter runs apprentice programs and ongoing training for its employees.

RELATED CONTENT

-

How Job Shops Can Generate Accurate Estimates in Minutes

New geometry-driven quoting technology lets job shops generate estimates in as little as 15 minutes. It enables them to respond faster to RFQs, drastically reduces time wasted on jobs they don’t get, and lets them focus on more profitable work.

-

From Job Shop Chaos To Lean Order

Classic lean manufacturing principles are practically taken as gospel, but benefits can be elusive for manufacturers that produce a variety of parts in low volumes. This shop took a different approach to lean—one aided by software that helped identify a more efficient machine layout based patterns in part routings.

-

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

.1692800306885.png)

.1687801407690.png)