Manufacturing is a global industry. Even at a time when companies are rethinking global supply chains, seeing the techniques of manufacturers and manufacturing technology from around the world can spark ideas for how to increase productivity, which is crucial to develop the capacity needed for reshoring. The NTMA recently organized a European Tech Tour, with stops at four OEMs in two countries. Along the way, attendees had the opportunity to experience the latest technology from these suppliers, and—because OEMs are also themselves manufacturers—learn from them.

Digitalization

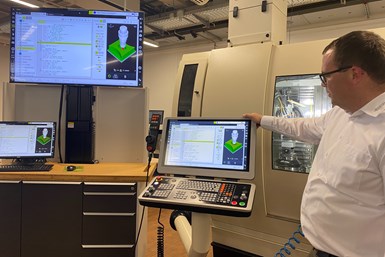

Heidenhain demoed its TNC 7 control during a tour of its headquarters in Traunreut, Germany. The control has many features that facilitate digitalization, including setup support with graphical models that walk machinists through the setup process.

Digital manufacturing was a recurring topic throughout the tour, beginning with the first stop at the Heidenhain facility in Traunreut, Germany. Although digitalization has the power to improve manufacturing in a number of ways, it also has its difficulties. As one Heidenhain employee put it, “The challenge of digitization is providing the right information to the right person at the right time.” Heidenhain’s TNC 7 control has a number of features that are designed to do just that: help funnel the right information to the right people at the right time. This includes customizable interfaces that ensure the user has access to the information they need without being distracted by unhelpful information. Programmers can also access a cutting data calculator with a material database and mechanical and thermal load adapters. Task-focused setup support walks users through setup with 3D models to ensure the process is fast and accurate. Additionally, the TNC7 has fully integrated process monitoring, detecting deviations from a reference machining run to monitor production.

Featured Content

At Big Kaiser (which is called Big Daishowa in North America)

Digitalization was also on display at the Big Kaiser facility in Rümlang, Switzerland, where the company showed its EWA boring head. The tool can function in a closed-loop system, with the machine tool measuring a bore and sending adjustments to the tool automatically.

in Rümlang, Switzerland, took this concept to the next level with its EWA boring head. The tool has closed-loop capabilities that remove the need for a person to make process adjustments. Precision boring can be a challenging operation, compounded by the fact that it often occurs at the end of production, meaning scrapping parts at this stage is costly. The EWA boring head can work semi-automatically, with the operator adjusting the boring head as needed via an app on a tablet or smartphone based on measurements taken either manually or via the machine’s probe. It can also work as a fully closed-loop system, where the machine tool measures the bore, uses code provided by Big Kaiser to calculate any necessary adjustments, automatically send those adjustments to the IPC, adjusts the tool and confirms the adjustment before machining continues. Closed-loop control of a cutting tool can result in shorter cycle times and higher productivity with fewer labor hours and reduced scrap rates.

Operation Combination

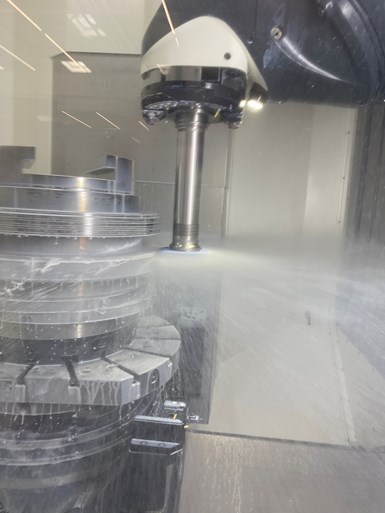

DMG MORI demonstrated several machines with multiple capabilities, including this DMC 80 FD duoBLOCK that performed dressing, grinding and rough turning.

Another theme was increasing efficiency by combining operations. The first mention of this came at at DMG MORI’s facility in Pfronten, Germany. The location serves as a hub for the company’s milling expertise, and all of the machines it produces here have five-axis capabilities. Five-axis machines themselves help increase productivity, but DMG MORI is expanding on this by combining milling with other operations, such as turning and grinding, to create a “universal machining center.” One demonstration showcased a DMC 80 FD duoBLOCK that performed dressing, grinding and rough turning of a large workpiece. According to the company, these universal machining centers are growing in popularity because they can help consolidate supply chains, improve part quality and reduce lead times.

Combining operations, although on a smaller scale, was also a topic of

Heule’s VEX-S cutting tool combines operations on a smaller scale. This tool combines drilling and chamfering with a solid carbide drill and the company’s SNAP system for chamfering holes.

discussion at cutting tool manufacturer Heule’s facility in Balgach, Switzerland the next day. Heule makes specialized cutting tools for operations such as deburring, chamfering and counterboring. One example is its VEX-S tool, which performs both drilling and chamfering by combining a solid carbide drill with its SNAP chamfering system. The solid carbide drill portion of the tool creates the hole, then the front cutting edge of the SNAP chamfering tool cuts the chamfer. As the tool continues into the drilled hole, the blade is forced back into the body of the tool, protecting the part from damage. When the tool is through the hole, the tool pushes the blade back out into position so it can debur and chamfer the back side of the hole. Then the blade is pushed back into the tool body so it can be fed out and move on to the next hole. This increases productivity and efficiency while improving part quality. It also means fewer tools in the toolchanger, and eliminates time for tool changes.

Apprentices

Both Germany and Switzerland have apprenticeship systems that all four companies take part in. Starting at age 15 or 16, apprentices spend two to three days per week doing hands-on training at a facility like this one on Heidenhain’s campus, while the other two to three days are spent in a classroom.

Digitalization and combining operations can both help increase productivity, but manufacturers still need skilled operators to run machines. Both Germany and Switzerland have a strong history and culture of training people for these positions via government-backed apprenticeship programs.

In both countries, apprenticeships start around age 15 or 16 and last between two and four years, depending on the program. Both countries also have a dual-education system, meaning apprentices typically spend two or three days per week at their apprenticeship, while the other days are spent in a classroom. In both countries, the federal government sets a curriculum for the company to follow, and the trainers who work with apprentices must be certified in order to standardize the education apprentices receive, regardless of the company. This education system is flexible, enabling students who complete apprenticeships to go on to higher education later.

All four companies had apprenticeship programs which featured heavily in the facility tours, and many of the tour guides were former apprentices. However, all of the companies noted that apprenticeship programs aren’t a magic bullet for solving the skilled worker shortage. The flexibility of the system creates challenges in retaining former apprentices for long, and companies noted struggles in recruiting new apprentices (likely due to larger demographic issues). But the groups of young people at all of the facilities, as well as the technology on display, served as inspiration and motivation for attendees to bring home to their businesses.

RELATED CONTENT

-

Improve Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

Performance Digital Comparators Offer an Alternative to Bench Amplifiers

Electronics today allow for matching the linear variable differential transformer performance and digital indicator size into a new digital comparator that provides even more value than traditional bench amplifiers.

.1692800306885.png)

.1687801407690.png)