Machine-Ready Blanks Help Shops Reduce Setup Time and Scrap

Machine-ready blanks from TCI Precision Metals are designed to help shops shorten setup time and reduce amounts of scrap. These blanks are ready to ship but can also be custom ordered.

Edited by

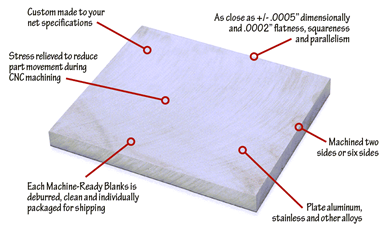

Founded in 1956, TCI Precision Metals is a family-owned precision manufacturer producing precision Machine-Ready Blanks from aluminum, stainless steel, and other alloys. Machine-Ready Blanks from TCI Precision Metals help shops shorten setup time, reduce scrap and increase overall throughput up to 25 percent by eliminating material prep, according to the company. Machine-Ready Blanks are designed to arrive machine-ready for production. Standard size blanks in low quantities are ready for immediate shipping, but customers are able to order custom, made-to-order blanks in production quantities for quick turnaround.

Precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and individually packaged to avoid damage during shipping. The blanks can be ordered online for same-day or next-day shipping, and arrive square, flat and parallel within ± .002” of specified dimensions all around. Custom made-to-order blanks are made to customer specifications and are guaranteed as close as +/- .0005” dimensionally and as close as .0002” flatness, squareness and parallelism.

RELATED CONTENT

-

Dillon Soft Jaw Blanks Feature Milled Surface

Dillon jaw sets reduce set-up times, aid concentric performance, provide better chuck balance and enable longer jaw life because of the increased jaw accuracies.

-

Sensory Clamping Devices Identify Defects Prior to Machining

IMTS22: Roemheld North America’s new sensory clamping devices enable operators to reject a faulty cast aluminum blank before any machining begins.

-

Starting with the End in Mind: An Exit Strategy for Machine Shops

John Shegda and Eric Wilhelm each had different ideas about how they wanted to phase into retirement. The exit strategies for the three successful manufacturing businesses the two men operated included a mix of seeking equity groups, selling the business, or transitioning into an employee stock ownership plan. All it took was a friendly suggestion from a mutual friend to set them on a different path.

.1692800306885.png)

.1687801407690.png)