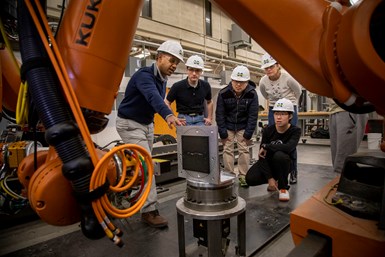

KUKA Robots Selected for Grant Research Project

University of Michigan research project on human-robot interaction uses three models of KUKA KR Quantec robots. Funding comes from a $2 million National Science Foundation Grant.

KUKA robots will be used for research conducted by the University of Michigan as part of a $2 million National Science Foundation Grant. The aim is to advance research that could result in robots working side-by-side with humans on building construction sites, KUKA says.

The University of Michigan will use three models of KUKA KR Quantec robots (the KR 120, KR 60 and KR 6) and its robot sensor interface (RSI) software, all of which are designed to enable human workers to use interactive task learning technology to teach the robots to perform tasks. For the research, the KR 120 is mounted on an external gantry while the KR 60 is on a mobile hydraulic excavator platform.

KUKA notes that its KR Quantec line of robots is suitable for a wide range of applications, which gives the University of Michigan the capability to upgrade payloads in the field as well as apply software add-ons to adapt to changing applications.

The research focuses on human-robot interaction in the construction environment specifically, which is uniquely challenging due to its unstructured and dynamic environment. In addition to the KUKA robotics, technology used in the research includes various automation software packages, sensors, point cloud scanners, tool mounted laser scanners and vision systems.

The NSF Grant was awarded to an interdisciplinary team and encompasses the collaboration of University of Michigan between the Taubman College of Architecture and Urban Planning and the College of Engineering in addition to external research partnerships with the University of Florida and Washington State University. The University of Michigan research team includes Wes McGee, an associate professor of architecture and director of Taubman College’s preeminent fabrication and robotics lab (FABLab); Carol Menassa (team lead), an associate professor of civil and environmental engineering; Vineet Kamat, a professor of civil and environmental engineering and electrical engineering and computer science; Joyce Chai, a professor of electrical engineering and computer science; Honglak Lee, an associate professor of electrical engineering and computer science; Arash Adel, an assistant professor of architecture; X. Jessie Yang, an assistant professor of industrial and operations engineering; and Curt Wolf, the managing director of the University of Michigan urban collaboratory .

RELATED CONTENT

-

Horizontal Machining Plus Automation Prove to Be a Rewarding Investment

After watching a machinist take four hours to set up a part on a VMC, Dan Olsen of Mach Machine knew he had a problem. The solution seemed clear: horizontal machining. The automation system wasn’t expected; but the novelty was well worth it before long.

-

No Such Thing as Luck: A One-Person Shop Owner’s Success Story

You could say he’s a lucky Guy. He has the ideal setup for a moonlighting at-home-machinist: The perfect location, the perfect day job, and a double-threat skill set that allows him to hire himself for prototyping and low-volume production work. But Guy Driscoll’s biggest talent might be creating his own luck.

-

CNC Optimization Software Reduces Cycle Times 25% or More and Can Double Tool Life

CGTech’s VERICUT Force optimization software can drastically reduce cycle times from 20-70%, even on supposedly optimized programs from CAM systems. It varies the feed rate to keep chip thickness and cutter load constant, which can increase tool life by 100% or more.

.JPG;width=70;height=70;mode=crop)

.1692800306885.png)

.1687801407690.png)