Hole Making as a Core Competency

This manufacturer leverages various nonconventional machining processes to create accurate holes in a range of tough materials. In fact, precision hole-making has become one of its specialties.

For some shops, hole-making operations are viewed simply as a necessity. For others, they represent a competitive advantage. LAI International is an example of the latter.

Headquartered in Tempe, Arizona, LAI has four U.S. manufacturing facilities that offer machining capabilities including CNC milling, turning, grinding and wire and sinker EDM. What sets the company apart from others, it believes, is the range of advanced, nonconventional machining processes it has refined over the years that are particularly effective for precision hole-making work in challenging materials. Specifically, LAI excels at applying high speed EDM drilling and laser and waterjet machining to create complex, shaped cooling holes in aerospace and power generation turbine components. These components are commonly made from Inconel, Hastelloy and other tricky high-temp alloys (some having metal-oxide thermal barrier coatings) to withstand the extreme heat generated in today’s turbine engines.

Featured Content

LAI’s expertise in these “process sciences,” as it refers to its specialized machining capabilities, enables it to determine the optimal hole-making operation for a given component. That’s because each has advantages and drawbacks depending on the application. Duringa recent visit to the Tempe facility, I learned about the company’s strides to become expert in its various nonconventional machining processes and how it applies these capabilities to create intricate holes for advanced turbine components.

Core Competency

LAI is a leading contract manufacturer of precision components and subassemblies for the aerospace, power generation, defense, medical and electronics industries. Its manufacturing capabilities extend beyond machining holes, although the company’s hole-making expertise is well-known and respected by its customers.

The company was founded in 1979 in Maryland, and its Eastern facility is located in Westminster near its original location. In 1994, LAI established an operation in Minneapolis, Minnesota to specialize in precision waterjet machining. In 2007, the company acquired Rich Technology International, a contract manufacturer in Scarborough, Maine that offered a range of conventional as well as nonconventional capabilities, including laser machining and high speed EDM drilling (also known as fast-hole EDM). It also recently consolidated two of its Southwest locations to establish the new Tempe headquarters, which offers laser and waterjet machining. The company has achieved ISO and AS certification as well as NADCAP certification for nonconventional and conventional machining. (In fact, it was the first manufacturer to achieve NADCAP certification for conventional machining processes.)

LAI’s three nonconventional processes are spread out over the company’s four facilities. In terms of hole-making work, they are applied primarily for aerospace and land-based turbine components, such as stage-one nozzles, blades, buckets, blisks, shrouds and vanes that often require numerous special-geometry holes to deliver specific flow requirements.

Having drilling expertise across multiple nonconventional machining disciplines enables it to determine the best operation for a given hole-making job. The material often dictates what process is most appropriate. For example, high speed EDM drilling is possible with conductive materials, but isn’t with non-conductive materials or materials with thermal barrier coatings. Those materials must be drilled via laser or waterjet.

The design function of the component also is considered. Some components require holes with specific, tight tolerances on size and spacing. In other cases, the holes are part of an advanced cooling system whereby the overall flow rate distribution is more important than maintaining closely repeatable hole dimensions.

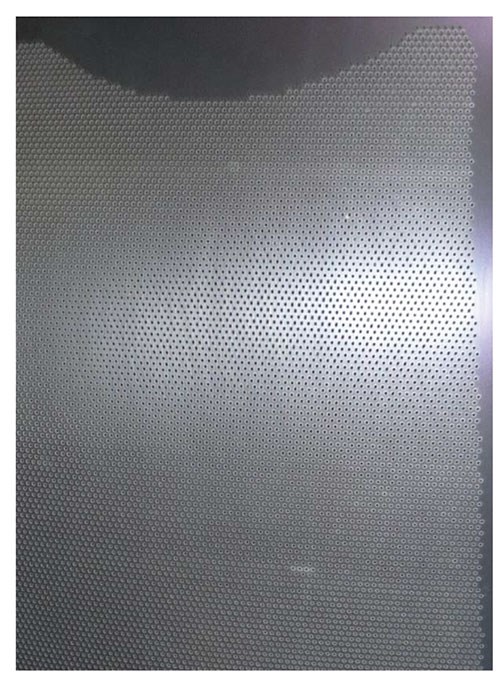

Hole surface finish oftentimes is more important than size, too, because it helps ensure that laminar flow is maintained throughout the cooling system. For these applications, the company has established a “drill-to-flow” approach to hole-making, which includes in-process and post-process flow bench testing of components to ensure they will deliver the customers’ specified flow rate no matter what hole-making method is applied.

Waterjet Hole-Making

Although a number of shops use abrasive waterjet primarily for rough-cutting operations or prep work for additional processes, LAI has established waterjet processes that enable it to perform precision hole-making and other operations. One advantage of waterjet machining is that it doesn’t create a heat-affected zone, which does occur when laser machining is performed. And unlike laser machining, it doesn’t create a recast material layer on the component that might require subsequent finishing operations to remove. It is also possible to drill through relatively thick material, which can be challenging with laser machining.

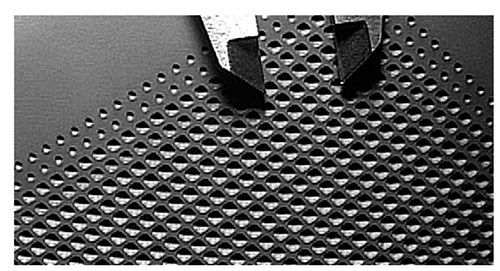

LAI’s Minneapolis waterjet production facility is home to its Waterjet Research and Development Center. Efforts there during the past 12 years have led to the development of the company’s drill-to-flow waterjet process for precision, shaped holes with diameters as small as 0.018 inch. Not surprisingly, waterjet is one process about which the company is hesitant to reveal too much proprietary information.

Darcy Dodge, vice president of strategic markets and products, says that the waterjet equipment LAI uses is 50 percent off-the-shelf and 50 percent LAI-developed technology, the latter consisting of intellectual property it keeps under wraps. This technology applies new approaches to abrasive media and jet pressure as well as equipment modifications to obtain the types of motion, speed and programming required to effectively create complex holes.

Most of the company’s waterjet equipment offers five-axis motion to create angled holes in turbine and other components. Hole angles for these components can range from normal to the surface to 25 to 30 degrees. Some machines include rotary tables for processing round parts, such as turbine buckets. Others have large, 6-by-20-foot beds that can accommodate multiple components for long stretches of unattended operation. The waterjet machines can routinely achieve diameter tolerances of ±0.001 inch thanks to LAI’s process engineering and strict adherence to a preventive maintenance schedule.

The flow testing occurs in-line with waterjet production (the same is true for laser and high speed EDM drilling). In some cases, the flow tolerances are so tight that a component might be removed mid-process for flow testing prior to completing the part. The company uses a verified master of each component to calibrate the flow bench and ensure changes in barometric pressure, for example, aren’t adversely affecting the bench readings. Pin gaging is performed on all holes prior to flow testing to ensure that holes are not blocked. In addition, some customers require pin gage measurements because they specify tolerances on hole size.

Laser Hole-Making

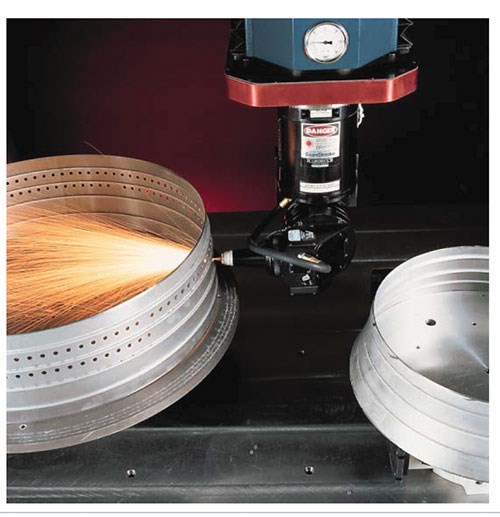

Laser machining is performed at the company’s Scarborough, Tempe and Westminster facilities. Some of these machines offer five-axis movement, while others combine tilting heads and a rotary table to enable six-axis machining. The company has both CO2 and Nd:YAG lasers, although the Nd:YAG lasers are more commonly used for drilling high-temp alloys. They are particularly effective for small-hole drilling operations because they offer high peak pulse power and less recast. It also is possible to effectively pulse through thermal barrier coatings because their high power density quickly penetrates the coating while preventing cracking.

LAI uses trepanning, percussion drilling and “drill-on-the-fly” laser processing techniques for hole-making operations. These processes enable the machines to drill holes ranging from 0.006 to 24 inches in diameter. With trepanning, the componsnt is held stationary while the laser beam is moved to create the periphery of a round hole or other shape. In contrast, percussion drilling delivers one or more pulses from the laser while both the laser beam and component remain stationary. The number of pulses depends on the material type and thickness, and the diameter of the hole that’s created is the same as the laser beam diameter.

Drill-on-the-fly is a variation of percussion drilling in which laser pulses are delivered from the stationary laser while the component is rotated or moved linearly. When multiple pulses are required to create each hole, the laser’s software synchronizes the movement of the part with the laser pulses, ensuring that the pulses repeatedly hit the same hole locations every time. The process can achieve hole diameter accuracy of ±0.001 inch on drilled holes. By changing the laser pulse energy, pulse count or lens focal length, hole size and taper can be controlled to meet the requirements of the component.

Drill-on-the-fly is possible because of the lasers’ auto focus control (AFC) capability. This feature involves “mapping” the workpiece surface to determine the actual shape of the part in the region to be drilled. The data from mapping is then used by the CNC to position the focusing lens assembly to maintain the correct laser beam focus position during drilling regardless of surface irregularities.

High Speed EDM Hole-Making

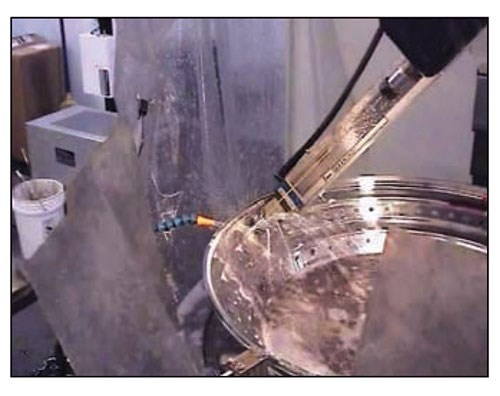

The Scarborough facility has seven high speed, six-axis EDM drilling machines. High speed EDM drilling offers faster drilling speeds than conventional EDM, especially for high-temp alloys and the proprietary, single-crystal alloy specified by one of the company’s key customers for single-stage nozzles.

High speed EDM drilling uses hollow electrodes made of copper or brass. The drilling speed is possible because the electrode is spinning at 3,000 rpm as it burns, and dielectric is delivered through its core to provide effective flushing. The spinning also minimizes electrode wandering, enabling the process to drill on curved or angled surfaces. Plus, it is possible to accurately maintain a consistent hole diameter at depths approaching 2 inches. This differs from drilling with conventional sinker EDM units and CNC machining centers, whereby deflection commonly occurs because the electrode or tool isn’t normal to the workpiece surface.

The EDM drilling speed largely depends on the size of the electrode being used. The rate of drilling slows as holes approach depths of 1 to 2 inches because flushing becomes less effective at relatively deep depths. It is also possible to drill blind holes and counterbores to a specific depth by using probing cycles that calculate electrode wear and the amount of workpiece material removed. These probing cycles determine how much additional drilling is needed to reach the desired depth.

Four of the machines are configured in a specific component cell tended by two operators. These machines offer XYZ travels of 60 by 30 by 30 inches, which is important because many of the components the cell runs are larger than other similar ones. LAI has also created its own EDM guides that enable the electrodes to access deep areas of the nozzles.

The machines also feature a 24-station tool changer that uses a FANUC LR Mate Robot with a two-position end effector to change up to 18 electrodes and 6 guides. The cell also has an offline electrode testing area that enables operators to test a holder, guide and electrode assembly to ensure there is no blockage of dielectric through the assembly. Poor dielectric flow would cause electrode deflection or the creation of oversize holes.

RELATED CONTENT

-

Machining 101: What is Electrical Discharge Machining?

Electrical discharge machining, or EDM, is a non-contact form of machining that projects sparks from an electrode or wire to vaporize material of any hardness.

-

Buying a Wire EDM, Part 4: Dielectric Fluid & Maintenance

Removing the microscopic particles made during the wire EDM cutting process becomes a key factor in maximizing cutting speed as well as attaining part accuracy and surface finish. Dielectric fluid is the mechanism for flushing these “chips” away.

-

Inside the Sinker EDM Process, One Spark at a Time

Successful sinker EDM operations rely on understanding the relationship between each individual spark, the electrode and the workpiece.

.jpg;width=70;height=70;mode=crop)

.1692800306885.png)

.1687801407690.png)